For many manufacturing organisations, the COVID-19 pandemic has highlighted a number of lessons. At IDC, we have observed two things: First, organisations that have already invested in their digital transformation (DX) have been less impacted by the pandemic. Second, manufacturing organisations that have been shifting their priorities from being efficient to being resilient have made their operations more flexible and agile.

Being resilient is key to ensuring innovation and achieving long-term business growth in a future that will continue to be uncertain and volatile. The Russia-Ukraine War first and foremost is a human tragedy but it will also have some severe economic impacts: supply chain disruptions, shortages of raw materials and key components, and rising energy prices.

These are not the only challenges for manufacturers. As a result of COVID, they have had to implement more resilient and flexible hybrid workplace concepts, accommodate workers’ changing preferences and recruit new talent with the right skills and young talent needed in industries with a high share of aging workers and lack of digital competencies.

Customer expectations are also increasing. This not only challenges manufacturers that have traditionally been selling to end consumers, such as CPG manufacturers, but also industrial B2B manufacturers. Direct-to-consumer (D2C) concepts, digital commerce and omni-channel commerce strategies are fairly new topics for industrial B2B manufacturing organisations — and need to be addressed in an already challenging economic environment.

At the same time, organisations need to embed sustainability goals into their operations and comply with supply chain transparency regulations. To tackle these challenges, manufacturing organisations need to utilise digital technologies — not only to survive, but to thrive.

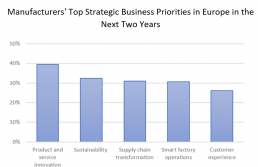

Manufacturers’ Top Strategic Business Priorities in the Next Two Years

Our research shows that the top 5 strategic business priorities for manufacturing organisations in the next two years are innovation, sustainability, supply chain transformation, smart factory operations and improving customer experience.

Product and Service Innovation: Addressing Rising Customer Expectations with Digital Technologies

Global competition and rising customer expectations are the main drivers of manufacturers’ investments in product and service innovations. IDC research shows that for 43% of manufacturers in Europe, product optimisation or product portfolio optimisation are the top innovation initiative. Incorporating customer feedback into product and service design processes by establishing feedback loops is another top initiative.

Digital technologies play a major enabling role in supporting these initiatives. Integrated product innovation platforms, for example, enable interdepartmental collaboration and collaboration with external stakeholders and enable closed loop feedback. Analytics tools, AI and IoT-enabled digital twin concepts will help to detect product optimisation potential based on product performance or behavioural data. We also expect manufacturers to increasingly utilise the “metaverse” as part of their investments around design and simulation tools, and for digital twins in the industrial context.

Sustainability — Increasing Demand for Environmental Accountability

Driven by the need to embed sustainability goals into their operations, the need to comply with supply chain transparency regulations and the business opportunities in “green business”, sustainability is a top strategic priority for manufacturers in Europe.

Top initiatives here relate to improving energy efficiency of supply chain and factory operations and the decarbonisation of factory operations. To reduce energy consumption, for example, analysing data from production equipment can deliver insights and recommendations on how to adjust machine parameters to reduce energy consumption. Enabling technologies are sensors, IoT, edge computing, cloud, analytic tools and AI.

But reducing energy consumption in production is just one example. Optimising transport routes to reduce the carbon footprint in the supply chain is another, as are platform solutions that enable circular economy concepts including product recycling and remanufacturing.

IDC predicts that by 2025, driven by stronger demand for environmental accountability in manufacturing ecosystems, 40% of G2000 manufacturers will use traceability technologies to mitigate risk and boost transparency.

Supply Chain Transformation — Shifting Towards Resilient Supply Chains to Reduce Disruption

Given ongoing supply chain uncertainties and disruptions resulting from a lack of resources and key components, ensuring supply chain resilience is key for manufacturing organisations. IDC predicts that by the end of 2022, half of all manufacturing supply chains will see the benefits of supply chain resilience, resulting in a 10% reduction in disruption impact. This will drive the digital transformation of supply chains accordingly.

According to IDC research, for manufacturers that consider supply chain transformation a key strategic priority, major initiatives include improved logistics and fulfilment planning and execution, real-time collaborative integration with trading partners, and improving supply chain real-time visibility.

Smart Factory Operations — Utilising Cloud, Edge and Automation to Avoid Factories Becoming Bottlenecks

Till recently, some companies have been wary of cloud, especially when it comes to mission-critical processes such as shop-floor functions. We are now seeing a major transformation, however, with digital transformation — and the process of connecting products and creating smart factories — putting new demands on modern organisations. Moreover, the use of AI to optimise factory operations requires on one hand large amounts of data to train AI models and on the other analytics capabilities.

The success of future operating models in a smart factory also very much depends on data management. By bringing together data and analytics to solve major challenges on the shop floor, in the warehouse or distribution centre, edge computing will also play a key role in transforming operations into more agile, flexible and resilient operations, and in improving operational performance and productivity. Manufacturers’ initiatives also aim to achieve a continuum of computing capabilities from the machine to the edge, to the data lake and the cloud. Continuity will be central here.

The past two years have also shown that automation is central in times when the physical presence of personnel, in the office and in the factory, are difficult to manage. In that context, greater automation — from RPA and digital workers to factory automation and robots — improves speed, flexibility, quality and consistency across all business processes. Investing in the automation of physical processes can help manufacturers to achieve resilience and ensure that the factory does not turn into a bottleneck and instead is a source of competitive advantage and innovation.

Customer Experience — Selling Beyond Traditional Products and Sales Channels in Industrial Manufacturing

Manufacturing organisations must secure revenues and boost margins. To achieve this they need to go beyond selling traditional physical products and onsite services because customer expectations are rising. Moreover, D2C concepts, digital commerce and omni-channel commerce strategies are fairly new topics for industrial B2B manufacturing organisations that need to be addressed in an economic environment that is already challenging.

IDC predicts that by 2024, 50% of industrial manufacturing organisations, driven by the pandemic, will have invested in B2B digital commerce — improving sales and marketing effectiveness by 15%.

Join IDC’s European Manufacturing Executive Community

There are many technologies out there that can help manufacturers to address all the challenges they face and pursue DX initiatives in 2022 and beyond.

IDC’s upcoming European Manufacturing Summit will encourage a dialogue between manufacturing organisations and technology providers on how to thrive in an increasingly digital and sustainable — but also uncertain, volatile and complex — economy. The summit, on November 15, 2022, will provide a great opportunity for manufacturing executives to discuss key issues, share lessons learned and network with peers.